Releases New Report on Global Dicyandiamide Market Revenue

Dicyandiamide Market – Snapshot

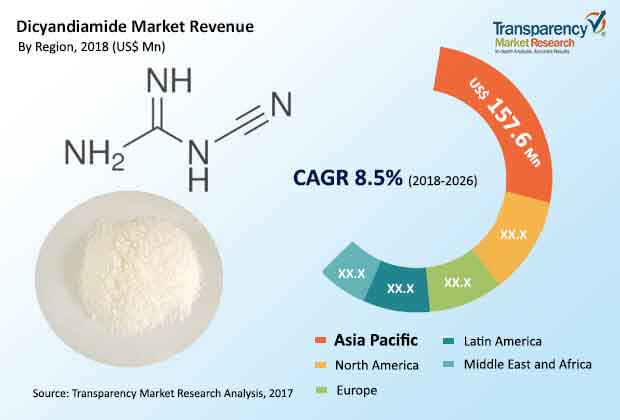

Dicyandiamide (DCD), which is also known as 2-Cyanoguanidine, is a alkaline, hydrophilic white crystalline compound. Dicyandiamide is primarily used as raw material for active pharmaceutical ingredients production for making anti-diabetic drugs. It is also used as a curing agent in epoxy resins and laminates for circuit boards and adhesives. It is also used in production of organic chemicals, which include, water treatment chemicals, slow and controlled nitrogen release fertilizers, dye fixing agents, and pharmaceuticals. Dicyandiamide are of different grades based on purity. The grades include pharmaceutical grade, electronic grade, industrial grade, and others. Currently, pharmaceutical grade dicyandiamide is mainly used compared to other types. The dicyandiamide market is expanding at a significant rate. Asia Pacific is anticipated to dominate the market during the forecast period, followed by North America and Europe.

Rise in Demand for Metformin from the Rising Diabetic Population across the Globe

Diabetes is one of the most common and rapidly increasing diseases across the globe. Diabetes is often referred to by doctors as diabetes mellitus. More than 400 million people across the globe are currently suffering from diabetes mellitus. Approximately 552 million people are anticipated to suffer from diabetes by 2030. Type 2 diabetes is the most common type and accounts for more than 90% of all cases of diabetes. Rise in diabetic population across the globe is ascribed to the rise in urbanization, changing population, increasing prevalence of obesity, and lack of physical activity.

Dicyandiamide is primarily used in the production of active pharmaceutical ingredients (APIs), which are used in production of metformin, a preferred drug for the treatment of type 2 diabetes mellitus. Metformin is also used in the treatment of excess weight and obesity. Metformin improves glucose tolerance in diabetic patients, lowering basal and postprandial plasma glucose.

Asia Pacific is the key metformin producing and exporting region across the globe. Hence, rising demand for dicyandiamide in this region is expected to drive the dicyandiamide market during the next few years.

More Trending Reports by TMR:

Availability of Cost Effective and Better Performing Substitutes

Dicyandiamide is used as an intermediate in the production of fertilizers, flame retardants, coatings, adhesives, etc. Melamine can also be produced using raw materials such as dicyandiamide, hydrogen cyanide, and urea. Melamine, in combination with formaldehyde and other agents, is used to produce melamine resins, which are used in high pressure decorative laminates. However, over the years, manufacturing processes for the production of melamine have been commercialized through the usage of dicyandiamide and urea.

Currently, manufacturers of melamine prefer urea as a raw material over dicyandiamide, as the urea process entails lower manufacturing costs. Furthermore, urea is more readily and easily available compared to dicyandiamide across the globe. Production of dicyandiamide is concentrated primarily in Asia Pacific and some countries in Europe such as Germany. Therefore, manufacturers have started replacing their melamine manufacturing process from dicyandiamide to urea since the last few years. Currently, all the melamine production facilities across the globe are based on urea. Thus, availability of cost-effective and better performing substitutes such as urea is anticipated to hamper the dicyandiamide market in the next few years.

Buy Now:

https://www.transparencymarketresearch.com/checkout.php?rep_id=42551<ype=S

Development of Non-toxic Ultra-micronized Dicyandiamide with Improved Performance

Ultra-micronized dicyandiamide grade is primarily used for epoxy powder coatings, film adhesives, electronic potting, etc. The ultra-fine particles have the storage stability of more than six months, which helps prevent settling and promotes uniform curing. Epoxy systems cured with ultra-micronized dicyandiamide offer superior adhesion, making it a preferred option for adhesive formulations. Furthermore, ultra-micronized dicyandiamide is compatible with all epoxy resins such as bisphenol A, novolac, etc. along with a varied range of pigments and fillers. Moreover, ultra-micronized dicyandiamide is non-toxic. These characteristics give the material an edge over its counterparts. Therefore, the development of ultra-micronized dicyandiamide, especially for epoxy coatings and manufacturing of adhesives and sealants, is expected to provide lucrative opportunities for the dicyandiamide market during the next few years.

Pharmaceutical Grade and Pharmaceutical Application Anticipated to be the Dominant Segments during the Forecast Period

In terms of grade, pharmaceutical has been a dominant segment for the past few years, and the trend is likely to continue during the forecast period. Dicyandiamide is used in the production of metformin, which is used in the treatment of type 2 diabetes. Rising diabetic patient population across the globe has created a need for the development of anti-diabetic drugs, which, in turn, is likely to drive demand for pharmaceutical grade dicyandiamide during the forecast period. In terms of grade, the pharmaceutical grade segment is anticipated to expand at a significant CAGR during the forecast period.

Comments

Post a Comment